At Guarda, we take our work seriously and work diligently to provide the highest quality products to our customers and distributed worldwide so consumers around the world can protect what matters most and have a peace of mind. We invest heavily in our engineering and R&D and vigorously develop and test new designs, materials, formulations, constructions and products. We do not just change things cosmetically so that it looks different nor just mimic what is on the market. We innovate! Our engineers and the team engage themselves deeply to develop new products and constructions and improve on existing so that it can be a better product. One of the major processes that we engage in is testing and we test at various steps of the R&D process. Why we consider ourselves a professional provider of fireproof safes and fireproof and waterproof safes is the in-house equipment we have to engage in standardize testing. Below we take a look at some of the in-house equipment we have that we use during our development, as well as for our quality processes and assessment.

Our computerized furnace allows us to recreate fire like situations to test the fireproof capabilities of our safes. Testing processes we follow include worldwide standards such the UL-72, JIS 1037-2020, GB/T16810. It allows us to see the temperatures inside during the testing process and we can test 30 minutes, 1 hour, 2 hours or even longer standards, and furnace temperature are controlled to follow the furnace temperature-time curve and furnace temperatures can go all the way up to 1200 degrees C plus. This furnace is used when develop new products or new constructions or formulations so we can see how performance varies and tweak and test. It is also used for quality assessments.

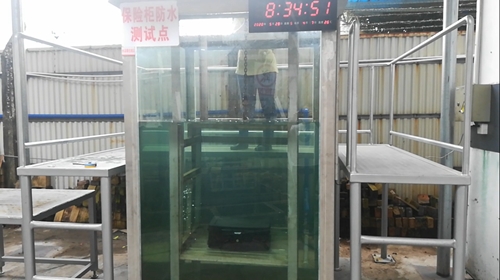

We also have a testing tank where we can test the waterproof capabilities of the safes. The testing tank is fully transparent which allows us to observe while test is ongoing. We can test a variety depths and timing and a rig allows us to move the safe up and down without strenuous labor.

Guarda’s manufacturing facilities also have an outfitted laboratory with a variety of testing equipment including transportation testers, drop test tester, tensile strength testers, humidity and temperature chambers, PCB rigs, measuring equipment, RoHS compliance materials evaluation machines as well as a team of personnel whom can develop and make testing rigs as needed.

At Guarda, we are serious about developing and making safes that meets and exceeds vigorous industry standards and we continuously invest time and effort into improving and developing new items that can help people protect what matters most, be it from all sorts of perils including fire and water. Browse through our website for more details about us and have a look through our wide range of off the shelf products including fireproof and waterproof safes chests for your selection. If you have an idea and want to explore it, our one-stop shop service can also help you getting it from paper to an actual product.

Post time: Oct-18-2021